Describe Where Internal Gears Are Typically Used.

For bevel gears an internal gear is one with the pitch angle exceeding 90 degrees. Large-capacity external gear pumps typically use helical or herringbone gears.

How Gears Work Different Types Of Gears Their Functions Mechanisms And Applications

They are used in applications where a right angle gear drive is required.

. Helical gears can bear more load than spur gears and work more quietly. Bevel gears are most commonly used to transmit power between shafts that intersect at a 90 degree angle. 4 Helical Gear Fig.

Gears are used in metal cutting machine tools. A gear is a rotating circular machine part having cut teeth or in the case of a cogwheel or gearwheel inserted teeth called cogs which mesh with another compatible toothed part to transmit convert torque and speed. A gear may also be known informally as a cog.

Term used to describe the pressure required to force liquid into a pump 1psi 231 ft of head. An external gear is one with the teeth formed on the outer surface of a cylinder or cone. The basic principle behind the operation of gears is analogous to the basic principle of levers.

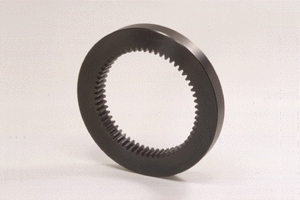

Internal gears are used for more specific applications such as a planetary gear set. Internal gears have teeth formed on the inner surface. It can mesh with a spur gear.

Defense is a very crucial industry as it is associated with the safety and security of the inhabitants of a nation. The main function of these gears is to provide force energy to the water within the pumps. Answer 1 of 2.

All bevel gears are assembled at its optimum position for best performance. In this type of gear teeth are cut parallel to the axis of the shafts so when is meshes with another spur gear it transmit the power in parallel shaft and when it connects with the. A pair of gears with many teeth external to the gear and called an external gear pump in gear pumps or a few lobes in lobe pumps is demonstrated in Fig.

These gears have teeth cut on the inside part of cones and cylinders and are used to pair with external gears. Internal means the teeth of one gear are on the inside projecting inward. Today we will describe most important types of it.

Bevel gears are generally more costly and are not able to transmit as much torque per size as a parallel shaft arrangement. Technical Information Characteristics top KHK stock internal gears are offered in modules 05 to 3 in 50 to 200 teeth. Internal gear definition a gear having teeth cut on an inner cylindrical surface.

Internal gear pump consists of two gears off center idle gear and power gears. Gears are primarily used in this industry in various types of weapons as well as in other components required for the proper operation of this industry. Although lobe pumps can be used in pneumatic applications they are typically used in hydraulic applications to move products such as slurries pastes and solids.

In mated pairs these gears employ the parallel axes configuration to transmit motion and power. Helical gears and spur gears are two of the most common gear types and can be used in many of the same applications. Note that bevel gears are usually a paired set and should not be used interchangeably.

These gears are used to transmit the power in same plane or when the driving and driven shafts are parallel to each other. Utilizes a similar spinning motion to propel liquid but the liquid moves in a straight line. External gear pumps can come in single or double two sets of gears pump configurations with spur shown helical and herringbone gears.

They can be used in. Basic Terms Used In Gear Calculation Last Updated on. The teeth of a helical gear are set at an angle relative to axis of the gear and take the shape of a helix.

They are always mated with an external gear with a smaller number of teeth. These are used in shaft couplings which are of gear types and planetary gear drives. Gear pumps may be external internal lobe or ___.

Bevel gears are assembled in a specific way due to its inherent transmission of both thrust and radial loads in contrast with spur gears which mostly transmit radial loads only. The short center-to-center distance of using an internal gear set makes it desirable for compact applications. Gear pumps are useful for pumping.

December 5 2020 by Saif M In this article youll learn what are the different Gear Terminology and Terms used in gear with calculation And also you can download the PDF file of. Gears are used to transmit motion from one shaft to another. Internal gear pumps use a gear within a gear design.

A gap or cavity is created between these two gears. Internal gears are often used in planetary gear systems. Conversely an internal gear is one with the teeth formed on the inner surface of a cylinder or cone.

The gear pumps essential as well as most frequently used pumps. Depending on the application they can be mated with another spur gear an internal gear such as in a planetary gear system or a gear rack such as in a. It is a toothed member designed to transmit or receive motion from another member by successively engaging tooth.

Displacement-volume of hydraulic fluid moved during each revolution. Rotary pumps use a variety of means to generate flow. Internal gears do not cause output shaft direction reversal.

Helical and herringbone gears typically offer a smoother flow than spur gears although all gear types are relatively smooth. Spur gears are simple and inexpensive to manufacture but helical gears offer some important advantages over spur gears. 14 Helical Gear This is a cylindrical shaped gear with helicoid teeth.

As the name suggests these pumps are inbuilt with gears. This is a cylindrical shaped gear but with the teeth inside the circular ring. In simple terms the function of this pump is to transfer the water from one location to another location with the help of gear instrument.

List and describe the 4 main pump ratings.

Internal Gears Khk Gear Manufacturer

Everything You Need To Know About Gear Studentlesson

What Is Gear Definition Parts Types And Benefits Engineering Choice

No comments for "Describe Where Internal Gears Are Typically Used."

Post a Comment